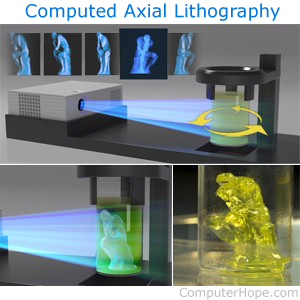

Computed axial lithography

Computed axial lithography is a 3-D printing technology developed by UC Berkeley and Lawrence Livermore National Laboratory. Announced in January 2019, it prints 3-D objects from the inside out and can create objects enclosed in other objects.

How it works

The 3-D object to be printed is modeled using computer software, such as 3ds Max. The model is rotated according to specific parameters and rendered to video. A special printer, called a replicator, rotates a clear cylinder, called a build volume, which contains a volume of translucent, photo-sensitive resin. As the cylinder rotates, the rendered video is projected at the cylinder. The video synchronizes with the cylinder, so the light corresponds to object being created next at that particular angle. The resin cures, or hardens, according to the intensity of light passing through it.

Potential benefits

The resulting 3-D object is created significantly faster than traditional 3-D printing methods, such as fused deposition modeling and stereolithography. Its surface is also smoother, lacking the "stair-stepping" edge artifacts of traditional layering methods.